Design is Thinking Made Visual

ISO 9001-2008 (TUV) COMPANY

SHREE VINAYAKA HARD CHROME (2016-2017)

1. INTRODUCTION

2. POWER

3. PLANT & MACHINERY

| 1 | Cylindrical grinding machine | Between centre 3.1 mtr. 250mm centre height |

| 2 | Belt polishing machine | Between centre 5 mtr. 350mm centre height |

| 3 | Belt polishing Lathe Machine | Between centre 3. mtr. 450mm centre height |

| 4 | Tank A | 800mm X 800mm X 11.5 mtr Long depth |

| 5 | Rectifier connected to tank A | 4500 (Ripple 5%) Amps , 12 volts , Thyristor control |

| 6 | Tank B | 1250mm X 1250 mm X 2 mtr depth Connecting 2000A Dimmer Control 12 Volts |

| 7 | Tank C | Dia 900 X 4.75 mtr long Connecting 4000 A Rectifier Dimmer Control |

| 8 | D Chrome Tank | 350mm X 350 mm X 7 mtr depth |

| 9 | Hoist | 5 Ton & 10 Ton capacity provided for both the tanks For loading & unloading, for belt polishing machine |

| 10 | Testing Equipments : | |

| a) Mitutoyo make Micro mtrs | Range 0 to 400 MM 12 Nos | |

| b) Thickness gauges | Range 0 to 100 micron ( manual type ) | |

| c) Electro physic make | Range 0 to 1000 micron ( prope type ) | |

| 11 | Hydrogen Demberment | up to 3.5 mtr long |

| 12 | Tank C | 1250x1050x3500mm (Depth ) |

| 13 | 2 No’s Lathes for Belt Polishing | 3 meter x 350 Center Height |

| 14 | Tank D | 1600 x 750 x 2000 mm Depth |

| 15 | Tank E | 880 x 2100 mm depth |

| 16 | Rectifier | 8000Amps , 16VDC with Dimmer |

| 17 | Lathe Machine | 1) Up to Dia 600 X 2.5 Mtr Length 2) Up to Dia 300 X 7Mtr Length |

4. MAN POWER

We are also undertaking job works for machining and heat treatment liketoughfning and induction Hardening .

5. Statutory Profile

| Income Tax PAN | AEOPR5830F |

| GST No. | 29AEOPR5830F1Z2 |

| Central Sales Tax No. | - |

| Value Added Tax Registration No. | 29600134512V |

| Excise Registration No. | - |

| Banker | CANARA BANK |

| Tan No. | BLRR05501G |

| Contact Person | Mr. Ramakrishn. P |

Customer Satisfaction

Customer satisfaction is our primary goal. We have over 300 customers all over India. Our professionals are also well-versed with the technological aspects of the machinery and frequently upgrade them to ensure enhanced production. Besides, our team members frequently interact with the clients to know their exact requirements and serve them accordingly. Moreover, our team members work in close synchronization to achieve the per-determined goals of the organization.

Quality Assurance

Customer satisfaction is our organization prime goal and we strive hard to achieve it with utmost dedication, supreme product quality and offered services. We have a team of quality experts who strictly check our products range at each stage of production. All our products range are designed and delivered as per the international standards. We regularly upgrade our techniques for the advancement in our technology.

Our Infrastructure

Our infrastructure helps us to complete bulk orders in the timely manner. We practice advanced techniques in the manufacturing of our entire product range. We have a proper space for documentation too, as it is one of the necessary tasks in the organization. Moreover, we have got a support of our trustworthy vendors, diligent team of experts and modern machinery. They all are the key ingredient in the success of our organization. With an area of 3000 square feet we have the sufficient space to conduct all our business processes.

Power

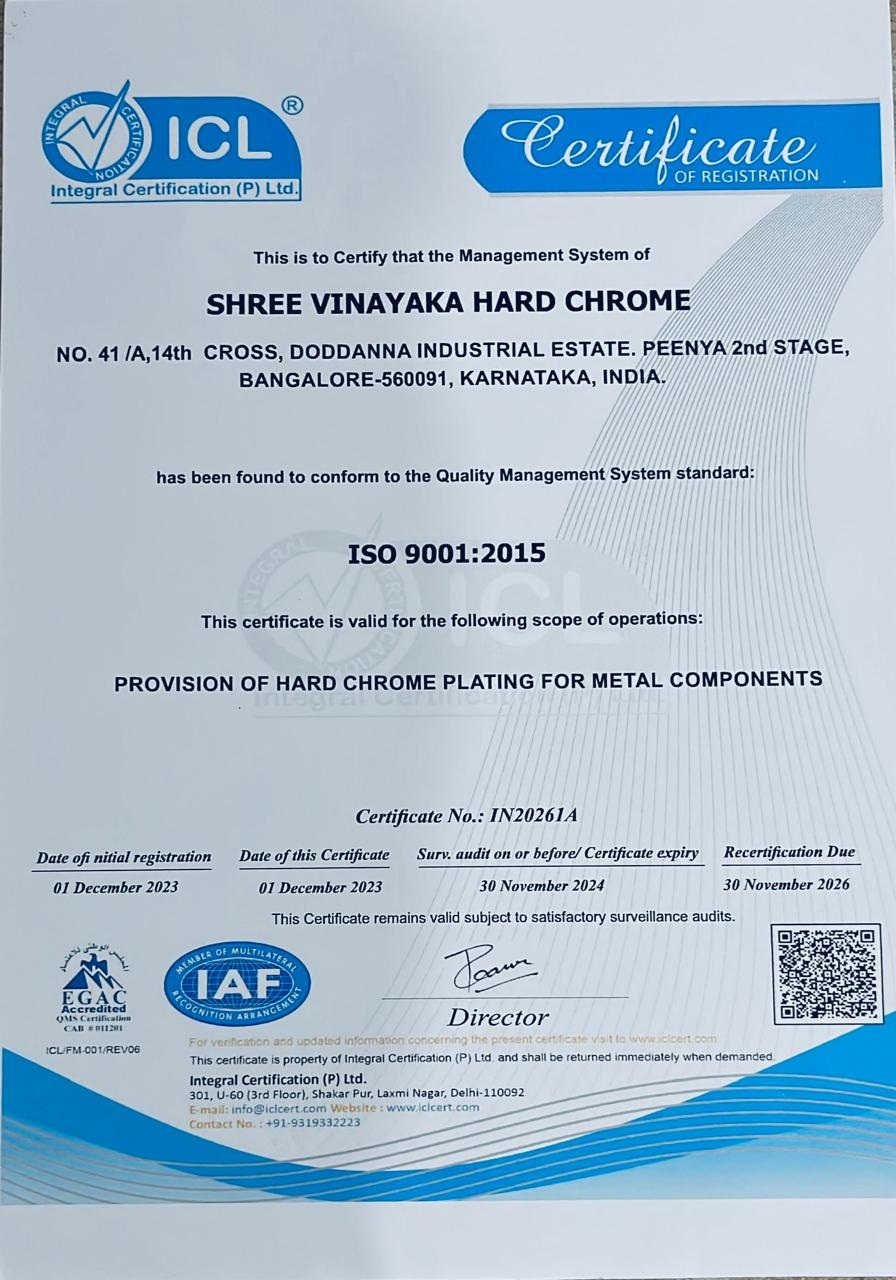

ISO Certificate

Our Vendor Base

A vendor plays a very crucial role in enabling an organization to transform client’s expectations into complete realization. Thus, we have made collaborations with industries renowned vendors to supplicate us with grade one materials. They are certified in their domain and always work as per our requirements. They never make delays while transits and always deliver consignments in promised time frame. Our vendors play a very crucial role in enabling the organization to transform client’s expectations into complete realization.

Strength

Hard Working, timely execution of orders, prompt compliance of customer complaint managing and leadership skill.

Our Team

We are backed by a dedicated team of skilled workforce and diligent personnel that helps us to meet the specific requirements of the clients.